Custom Control Panel: Design, Fabrication and Contract Manufacturing

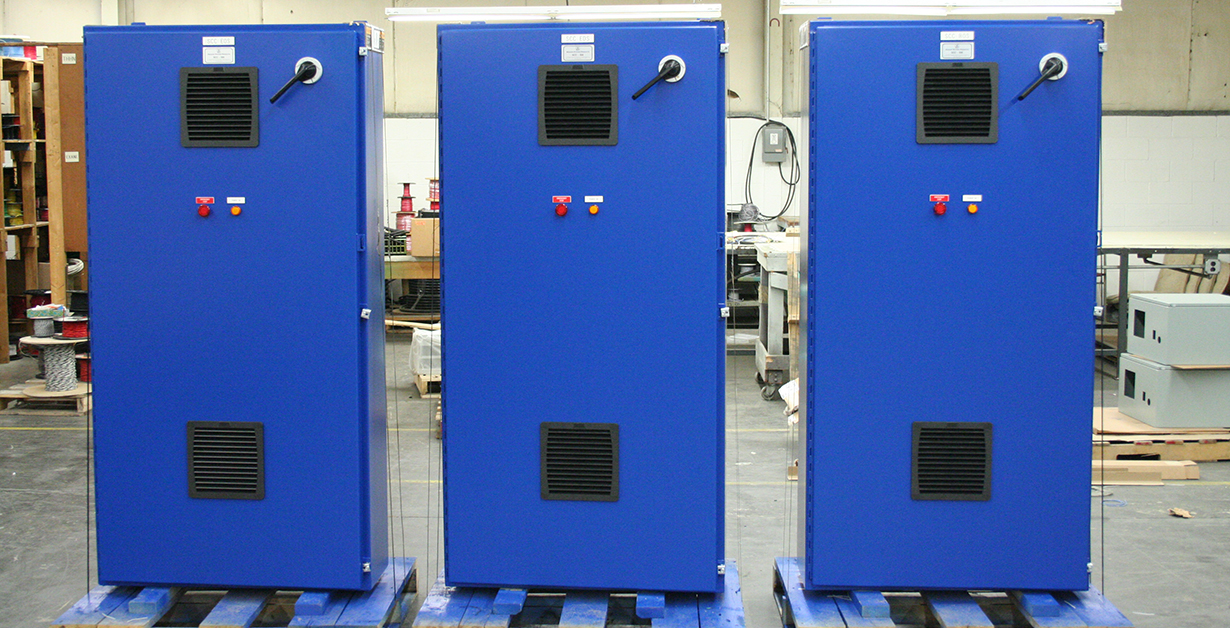

Staneco Corporation specializes in providing the design, fabrication and contract manufacturing of custom control panels. By combining fabrication, manufacturing and design services, we provide our clients with single-source responsibility.

This turnkey approach ensures each project is completed on schedule, within your budget and according to your specifications.

We also supply many clients with manufacturing services on projects where the design work is already finished. By using customer schematics, P&IDs and engineered documents, we can meet their fabrication needs.

These jobs might be something as simple as push-button stations, or as complicated as multiple door enclosures or complex piping skids.

But whatever you require, know that we treat every job with the utmost importance because we understand your success equals our success. Staneco Corporation provides custom control panel design and fabrication, using the Hoffman Steinhauer Modcenter 293 for automated control panel building.

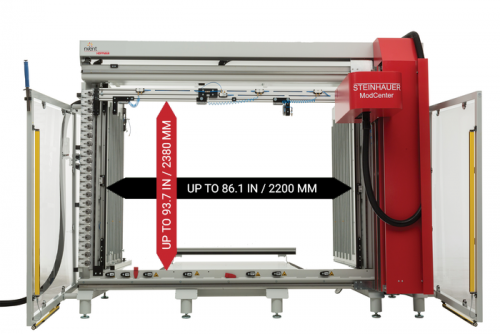

Introducing Hoffman Steinhauer ModCenter 293

Using the versatile Hoffman Steinhauer ModCenter 293 for automated control panel building allows us to pass along amazing direct benefits to our customers. ModCenter 293 enhances quality and accuracy, increases productivity, and improves efficiency leading to faster turnaround to our customers.

Contact us for more information >

Key advantages of automated custom panel and enclosure modifications:

ENHANCES QUALITY

- Use of state-of-the-art design and controls ensuring repeated precision

- Back panel drilling and tapping are completed simultaneously for improved quality and standardization

- Machined enclosure cutouts

- Processes a variety of materials including steel, stainless steel, copper, aluminum, PVC, and glass-reinforced plastic (GRP)

REDUCES COST

- Productivity using machine is increased by 30%

- Allows for efficient repetition of multiple panels

- Can mill mild steel at 78 IPM, making a 4 x 4 inch cutout within 3 minutes

- Accommodates a wide range of enclosure dimensions up to 93.7in Tall by 86in Wide

- Handles back panels up to 92in Tall by 94in Wide

IMPROVES EFFICIENCY

- Seamlessly accepts AutoCAD and EPLAN arrangement drawings

- No need for manual measuring, marking and taping... Machine uses software for expedient and precise layout

- Machine-drilled, fast, cleancut holes and cutouts utilizing best-in-class cutting speed

- By quickly modifying a blank panel, we significantly reduce assembly time